For four years, the Littoral Mission Vessel (LMV) existed as two-dimensional blueprints in the minds of those in the LMV Project Office. But blueprints don’t fight wars — warships do. With key portions of the designs finally signed off in early 2014, it was time to turn the dreams into a living, fighting warship. In other words: all hands on deck.

Some Assembly Required

The average car has about 30,000 different components, counting down to the smallest screw. The parts needed to assemble a warship, on the other hand, number in the millions. The cables that run through the walls and floors of the LMV, the first ship of its kind, alone add up to about 280 kilometres. That’s enough to stretch the entire length of the Pan-Island Expressway — which itself spans the length of Singapore — six times over, with about 500 metres to spare. Putting a warship together is not a job for the fainthearted.

1. Steel Cutting

This is when steel plates are cut and welded to form the hull and deck sections of the ship

2. Keel Laying

The cut steel is assembled into smaller blocks, which are in turn assembled to form larger sections of the ship — like LEGO sets

3. Launching

This is when the ship slides off the dry dock into water for the first time. A bottle of champagne is smashed against the ship at launch to invite good luck

4. Sea Trials

This is when the ship is put through a gamut of tests out at sea — an important step before she is deemed to have met design specifications

5. Commissioning

This is when the ship goes into active service and is ready for deployment

It began with steel cutting, where steel plates are cut and bent to form the hull and deck sections of the ship — the body and armour of the LMV, if you will. Next came the keel-laying process. Project leader, SLTC Chew Chun-Chau explains, “It’s like building skyscrapers. People don’t build brick by brick anymore. They prefabricate sections individually, which are then fixed together. It’s the same for shipbuilding.” In total, 18 prefabricated keel blocks, consisting of the 10 double-deck Bottom-Blocks and eight single-deck Upper Blocks, form the body of the LMV — and that is not including the composite superstructure and the pole mast.

While the bigger pieces were being put in place, the smaller components had to be taken care of as well. ME3 Iris Leow, the communications cluster chief on board the LMV, was in charge of planning the communication network within the ship, which is more complicated than dragging phone lines from one end of the ship to the other. Instead, she studied the route of each communication line — where they needed to go and how they needed to get there — right down to the placements of communication equipment.

This includes the placement of speakers, notes ME3 Leow. "You cannot put it too near to the bedside, because it will scare the crew sleeping here. But this is a ship, and space is limited, so you have to find creative ways to make things work." This means rerouting speakers, reworking the interior designs or finding smaller, more compact speakers altogether.

And that’s just the speaker. Little adjustments like that happen across the ship all the time. For ME3 Leow, however, the satisfaction comes from seeing a two-dimensional design come to life. "It’s also about applying 10 years of experience working on a patrol vessel onto this new ship, and I am definitely very proud of that."

The Right Men (and Women) for the Job

It was also around this time when SLTC Chew approached LTC Tay Choong Hern to become the commanding officer (CO) of the new LMV. At the time, LTC Tay was still the CO of patrol vessel RSS Fearless. When he learnt the capabilities of the new LMV, any hesitations to take over command soon went out of the window. "Some things happen once in a tour; some things happen once in a blue moon. To command a first-of-class ship, that’s once in a lifetime."

More than just the commander, a warship is only as powerful as its crew, and it’s not just about putting together the best of the best. How individuals work together will make or break the ship as well. That is why close to half of the pioneer crew is made up of members of the LMV Project Office — or those that have already established a rapport working together since day one.

"My main mission is to ensure we are a crew that works with the vessel, and that it works in the real world. We are the test pilots. The crew needs a willingness to explore, and break free from old ways."

LTC Tay Choong Hern

Commanding officer of RSS Independence

“We need passion and conviction to stay on course for such a long project. Otherwise when there are challenges, you may swerve; you may give up.”

LTC Chew Chun-Chau

Project Leader of the LMV Project Office

It also helped that, before the LMV was launched, the crew went through rigorous training to prep them for future missions. Original Equipment Manufacturer courses were conducted to familiarise the crew with the equipment on board. “But that’s just the systems and machines,” LTC Tay says. “To gel the team, we had to go through team-level training as one.” This included damage control, firefighting, small arms, and full-fledged ship simulator trainings. None of the training was easy going, but the result was a seaworthy crew that’s ready for anything.

Perfection in the Details

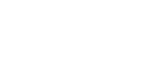

With the ship finally taking shape and crew trainings underway, it was time to focus on the ship's finer details. "The engine needs to work with the shaft line; the shaft line needs to work with the gear box; the gear box needs to work with the propeller. [The parts] have to operate as a system of systems," SLTC Chew explains. Complicating matters further was the fact that the parts came from, by SLTC Chew’s estimates, over 10 different countries and 20 different contractors. These parts had to be connected to a central computer, which had to then be programmed to make everything work in tandem. “There were many, many rounds of tests," SLTC Chew says with a stoic smile.

Human factors, or the application of human psychology to the design, were taken into account as well. To that end, the crew — those for whom the LMV will be a second home — were invited to contribute their inputs during the construction stage. For example, when LTC Tay boarded the Integrated Command Centre (ICC) for the first time, he noticed that pillars were blocking his line of sight. "The pioneer crew gave our recommendations, like maybe this seat can be put further back or adjusted higher to avoid the pillars, or it has to traverse from one side of the ICC to the other for a 360 [degree] view," LTC Tay says. "It was heartening to see, even now, that our inputs were implemented." In fact, based on LTC Tay’s feedback, the pillars were eventually removed.

23

65dB>

20–24°C

Leading the Way

By early 2016, just 13 months after the first steel plate was sliced into shape, the LMV was ready for launch. SLTC Chew still grins when he remembers when the hull of the ship touched water for the first time: "When a ship sets sail, [the crew] will communicate back to HQ that they are out at sea. I remember the first time ME3 Leow reported back to us, checking in and saying that they were setting sail from the shipyard. It was such a surreal moment."

The crew, too, had come a long way. LTC Tay remembers the first time the pioneer crew met face to face — over a casual barbecue bonding session no less. "I told them that, as the pioneer crew, our purpose was not to be the most elite or the most unique," SLTC Chew recalls. "It's to lead the way for others to follow."

With bated breath and beating hearts, it was time to put the crew and the ship to the test, literally. Let the sea trials begin.