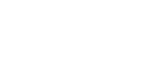

(Caption of photo above)

ME4 Vincent Sin (pictured left) and ME3 Johnny Ker work behind the scenes to 3D-print the "ear savers".

In addition to ensuring our ships' system readiness, they also find time to innovate and build up 3D-printing capability in the RSN.

Over the past three years, the 3D-printing team expanded from a small initiative with a single printer to an outfit with three printers and a 3D-scanner.

When our 3D-Print team from the Systems Readiness Engineering Centre (Marine and Electrical) (SREC (M&E)) learnt about the "ear savers" that the maker community in Singapore were making for our healthcare workers, they were inspired to do the same for our navy medical centres!

"We want to ensure that our navy medical centre personnel are not forgotten, and to show our appreciation for their contributions as we stand our watch during this COVID-19 pandemic" - ME6 Tan Meng Hwee, CO SREC (M&E)

Using masks for extensive periods of time can put a strain on the ears. In the humid weather, medics often feel discomfort and pain.

"This initiative helps reduce the pressure on our medics' ears and head. It gives them some comfort while they do their duties at the front line." - ME3 Kevyn Yeo, Senior Medic from Tuas Medical Centre

ME4 Vincent Sin (pictured left) and ME3 Johnny Ker work behind the scenes to 3D-print the "ear savers".

In addition to ensuring our ships' system readiness, they also find time to innovate and build up 3D-printing capability in the RSN.

Over the past three years, the 3D-printing team expanded from a small initiative with a single printer to an outfit with three printers and a 3D-scanner.