Web Content Viewer

Web Content Viewer

In this week’s 55th Anniversary of National Service (NS55) feature, let us take a closer look at the evolution of our Army’s personal equipment. As Singapore’s National Service first started in 1967, our personal equipment has evolved over the years with the advancement of technology. As part of meeting Singapore Armed Forces’ (SAF) operational and training requirements, SAF continuously reviews personal equipment to cater to the different needs of our soldiers.

We spoke with Military Expert 3 (ME3) Kuan Yoke Gei who is from OETI Engineering School, HQ Army Logistics Training Institute (ALTI) and her son, Second Sergeant (2SG) Dylan Lieo from the 30th Battalion, Singapore Combat Engineers (30 SCE), who enlisted in different generations, to share with us about the transformation in our Army’s personal equipment.

No. 4 Uniforms

1970s: ‘Temasek Green’

Key Features:

1. Cotton Material

The uniform is made from thick cotton drill.

2. Starching of Uniform

Temasek Green uniforms were highly starched and pressed so well that the shirt would stand on its own for foot drills.

3. Standardised Uniform

All military services, Singapore Armed Forces (SAF), Republic of Singapore Navy (RSN) and Republic of Singapore Air Force (RSAF) wore the same ‘Temasek Green’ uniforms. This same uniform was also used for field training.

1980s: First Camouflage Uniform

Key Features:

1. Camouflaged Design

The uniform design is influenced by American-developed camouflage patterned cloth with the use of black, forest green, browns and tans.

2. Improved Fabric Material

A different material was introduced, effecting better air permeability and lighter weight fabric than the ‘Temasek Green’ uniform.

2008: 3rd Generation Pixelated Uniform

Key Features:

1. Pixelated Design

The pixelated design which generates micro-pattern within its macro-pattern and the lighter green colour of the uniform helps to provide better camouflage and improve stealth for our soldiers.

2. Fewer Buttons, More Velcro

The shirt pockets are also secured using velcro to relieve pressure when soldiers don their body armour.

3. Polyester and Cotton Material

The uniform is made from 50/50 polyester and cotton blend with enhanced wicking ability which allows for quick absorption.

4. Special Functions

The uniform material is given Near Infra-red (NIR) treatment to escape night vision detection and is also coated with a special chemical that keeps mosquitoes away.

2018: Hybrid Uniform

Key Features:

1. Flame Resistant

The high-performance fabric has self-extinguishing abilities and is resistant to catching fire. Hence, it does not melt or drip when exposed to extreme heat.

2. Good Air Permeability

The high-performance fabric is made of porous construction that allows better air circulation. It is 40% more permeable as compared to the No.4 uniform.

3. Effective Wicking and Drying Properties

The high-performance fabric absorbs perspiration and dries quickly. It is 60% more effective in drying as compared to the No.4 uniform, and reduces the risk of heat injury during outfield training.

Helmets

1970s: ‘Steelport’ Helmet

Key Features:

1. One Size Fits All

The helmet did not have multiple sizes, only one size. Sponges had to be slipped in between the inner liners for maximum comfort and a snug fit.

2. Plastic and Steel Material

The inner liner was made of plastic and the outer layer of solid steel, thus its name ‘Steelport’.

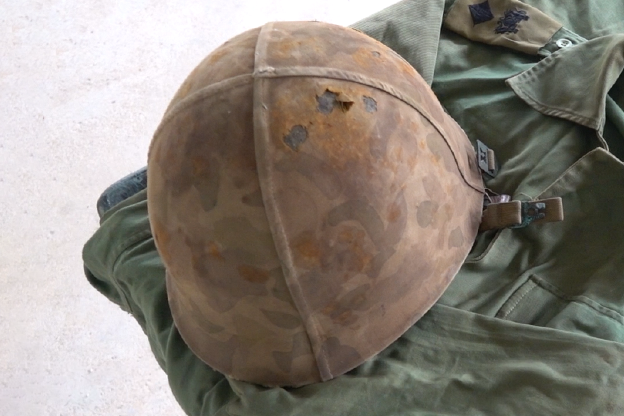

Late 1980s: Kevlar Helmet with Camouflage Net

Key Features:

1. Kevlar Material

The helmet is made from kevlar, a light but strong synthetic material.

2. Camouflage Net

The helmet is covered by a camouflage net for better camouflaging as compared to the ‘Steelport’.

2020: Ergonomic ‘High-Cut’ Helmet

Key Features:

1. Adjustable Padding System

The helmet has an adjustable padding system that allows soldiers to ensure the helmet fits comfortably and offers protection against impact injuries.

2. Lighter In Weight

The helmet weighs approximately 10% lighter compared to the previous in-service helmet, enabling soldiers to sustain longer and improve their overall combat performance.

3. High-Cut Design

The high-cut design allows better interoperability with other head mounted systems such as Night Vision Devices and Communications Headsets.

Field Pack

1970-80s Field Pack

Key Features:

1. Sufficient Support

The field pack is made of a denim-like fabric with two unpadded metal bars crossing the back of the pack for support, and two side pockets. The pack was secured by two straps and could be uncomfortable when carried over long distances

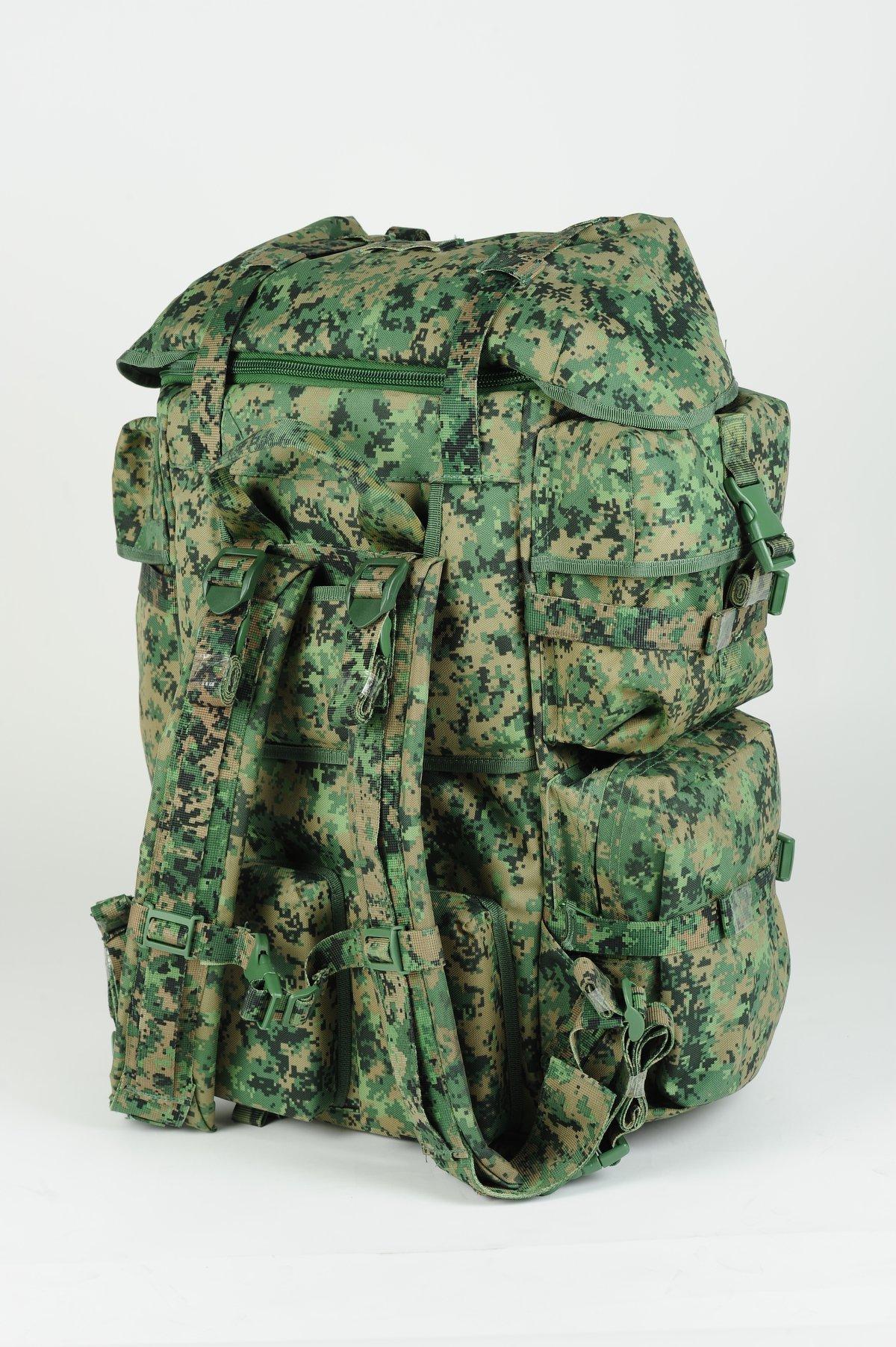

2015 Field Pack

Key Features:

1. Ergonomically Designed

Multiple openings for ease of packing and unpacking in the quickest way. On top of that, the four-way compacting straps offer stability and manoeuvrability. During an emergency, quick-release buckles on shoulder straps can be easily unbuckled to discard the pack.

2. Configurable Rack Systems

The configurable rack system for different load requirements, able to carry loads of up to 80kg.

Using technology to introduce ergonomically designed personal equipment for soldiers, the Army is able to improve combat effectiveness to improve training safety and ensure mission success. In celebration of NS55, let’s look back and appreciate the evolution of our Army’s equipment. We would like to thank those who have been involved in developing and improving it throughout the years, enhancing our soldiers’ efficiency and quality of life while out training hard in the field to protect what is ours. Ready, Decisive, Respected!

Check out our Evolution of Personal Equipment (Mother and Son Edition) video here!